All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

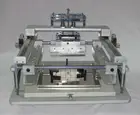

Torch T1000 PCB Manual Stencil screen Printing Machine for smd led

No reviews yet

Key attributes

Industry-specific attributes

Condition

New

Color & Page

Other

Voltage

220V

Other attributes

Applicable Industries

Manufacturing Plant, electronics

Place of Origin

Beijing, China

Automatic Grade

Manual

Weight

46KG

Warranty

1 Year

Key Selling Points

Easy to Operate

Plate Type

Screen Printer

Brand Name

Torch

Usage

Screen printer

Dimensions(L*W*H)

620 x 550 x 500mm

Certification

CE ISO9001

Name

Torch T1000 manual stencil screen printing machine

max printing area

300 * 400mm

stencil size

350*450mm

Expected printing accuracy

0.4 IC; BGA > 0.3mm Raster

Ajusting accuracy

< 0.01mm

Expected printing speed

60 - 100 pcs/h

Application area

pcb board

Packaging and delivery

Packaging Details

Plywood Box

Dimension: 72*67*55cm

Weight: 40/56kg

Dimension: 72*67*55cm

Weight: 40/56kg

Port

Beijing, Tianjin

Supply Ability

Supply Ability

1000 Unit/Units per Year

Lead time

| Quantity (sets) | 1 - 5 | > 5 |

| Lead time (days) | 10 | To be negotiated |

Know your supplier

Product descriptions from the supplier

Minimum order quantity: 1 set

$2,200.00 - $2,500.00Variations

Total options:

Shipping

Shipping solutions for the selected quantity are currently unavailableMembership benefits

Quick refunds on orders under US $1,000Claim now

Purchase detailsProtection with

Purchase details

Protection with

Secure payments

Secure payments![]()

Every payment you make on Alibaba.com is secured with strict SSL encryption and PCI DSS data protection protocols

Refund policy

Refund policy![]()

Claim a refund if your order doesn't ship, is missing, or arrives with product issues